Sample Preparation Hints

Sample preparation is critical and can dramatically impact the quality of your collected data.

Please contact 11-BM staff with any questions on sample preparation before shipping your sample(s).

Read the suggestions below for several hints on sample preparation. See also the 11-BM Mail-in User Instructions (.pdf).

For each powder sample or composition; consider the following:

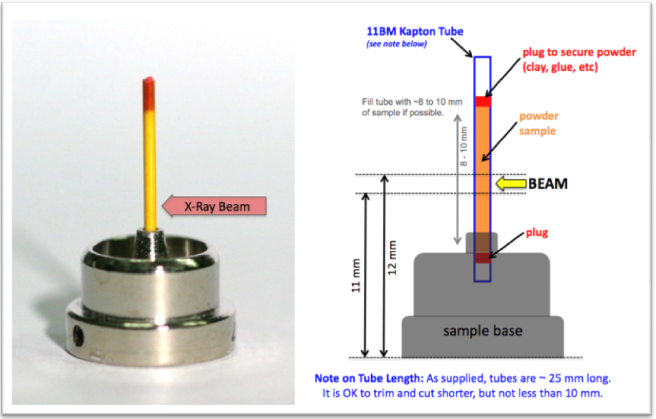

Sample Position & Containment: Sample powder must be located in the beam position when mounted by the 11-BM robot (see diagram at bottom). Other materials (glue, wax, clay) in the beam position will add peaks to the diffraction pattern. Powders must be fully contained & sealed in the capillary, and must not shift during shipment or when spun (> 60 Hz) during data collection. Supplied capillaries should fit snugly inside 11-BM sample bases without a need for glue. A capillary is sufficiently secure if you can hold a base upside down without the capillary falling.

Particle Size & Morphology: Ideally, all sample powders would have a small (~5 micron) and homogeneous particle size and shape distribution. In reality, this is not always possible or practical. However, please do consider how non-ideal powder size or shape distributions impact your data. Large crystallites tend to reduce particle counting statistics, while very small (or strained) particles will result in peak broadening. Nano-materials may have VERY broad peaks.

X-ray Absorption: In general, heavy elements (high Z) absorb X-rays more strongly than light elements (Pb vs Be). 11-BM uses transmission (Debye-Scherrer) geometry; therefore sample X-ray absorption must be considered. Absorption is not normally an issue for most mail-in users; the high energy beam (~30 keV) easily penetrates these sample powders. However, for samples containing a large fraction of high-Z elements, absorption can be problematic unless special care is taken. See our webpage for more information and a web based X-ray absorption calculation tool.

Radiation Damage: Ionizing radiation from the intense synchrotron beam can induce damage in samples via several mechanisms. While oxide or metallic samples are largely unaffected, samples containing organic materials may suffer radiation damage (e.g. proteins, MOFs, pharmaceuticals, etc). Cooling samples during data collection can help to minimize this effect, but the extent of damage at any temperature is hard to predict in advance. If obvious beam damaged is observed during data collection you will be notified. Collection strategies are available at 11-BM to reduce the impact of radiation damage; contact beamline staff for more details.

Atmosphere & Temperature Stability: Ensure that sample powders and containment materials (wax, glue, clay, etc) are compatible with the scan temperature(s) requested. Air or moisture sensitive sample may be sealed inside the Kapton tubes using epoxy; however, the gas permeability of Kapton is not guaranteed. Alternatively, first seal sensitive powders in a glass or quartz capillary. However, this inner capillary MUST also be contained and fit completely inside the supplied Kapton tubes. These samples should be clearly marked for special handling and will be rejected if the glass/quartz capillary is not enclosed in Kapton. Inquire with beamline staff about special sized sample mounting bases and double nesting Kapton tubes if your permissible samples are particularly hazardous or air sensitive.

Figures below illustrate a properly prepared sample for the 11-BM mail-in service, including the position of the X-ray beam on the sample capillary tube. Red material visible at the capillary tip is modeling clay used to secure powder inside the Kapton tube. See the 11-BM webpage for larger images and advice on sample preparation.